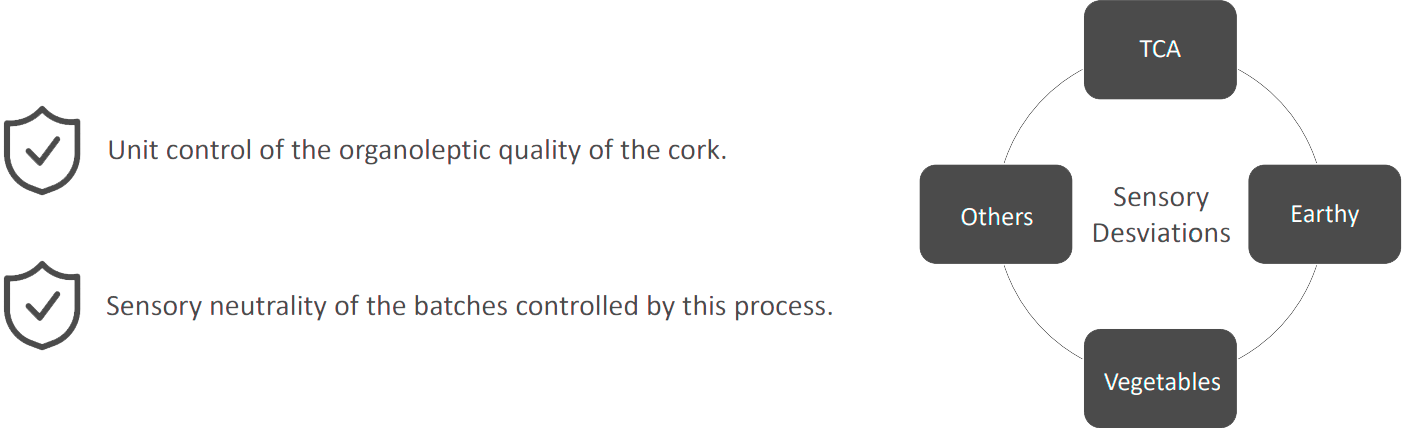

Unit Control Technique

The SaInov process guarantees sensory neutrality in the controlled batches, aiming at the absence of organoleptic deviations in the wine.

The SaInov process guarantees sensory neutrality in the controlled batches, aiming at the absence of organoleptic deviations in the wine.

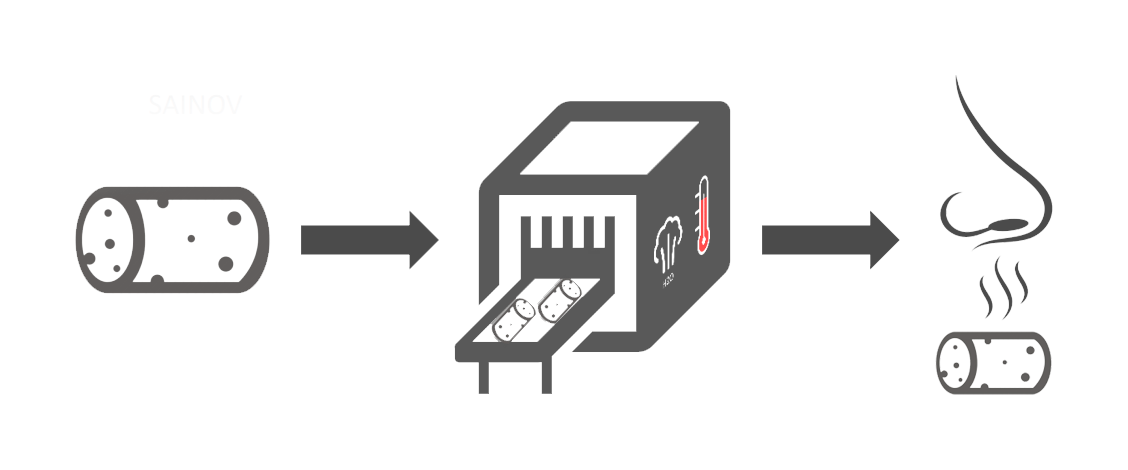

During this procedure, the cork stoppers pass through a tunnel, where they are subjected to light steaming.

After that, the corks continue their journey through the tunnel under high temperature conditions, resulting in a thermal shock. This operation promotes the release of volatiles.

At the end of the tunnel, a technician trained for this purpose (sensory analysis) smells the cork, allowing an assessment of the cork's sensory level.